Well, since we are kind of on hold with cutting out the sides and the CP on the CNC Router, I decided to work on stuff I could be making. So today I made the back panels. I know this is the last thing that will actually go on the cab, but it was work that could be done and progress that could be made.

The monitor “shelf” is in the middle of the cab and had a fan mounted in it to move air up through the cab for cooling. This means we need slots in the bottom and top for air flow. No one will ever see this part of the cab. It will be up against the wall. However, I am OCD and was not content with simple slots, so….

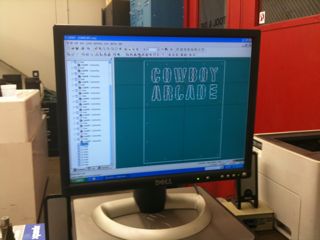

I drew what I wanted and we converted it to code for our CNC mill.

Then we clamped up and indicated in the blank material (1/8″ Work Tempered Hardboard):

Then loaded up the program and started cutting:

We are using an 1/8″ carbide endmill so there will be a 1/16″ radius on all inside corners.

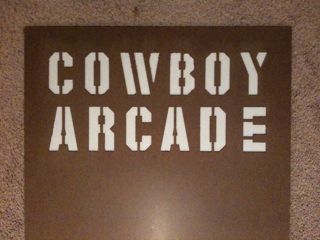

Here is the first piece finished:

Then we clamped up and dialed in the second piece and ran the second program:

Continuing the cuts…

The endmill ‘frayed’ the edges a little but we took a sanding block and ran over everything and it cleaned up great:

So the completed cuts: TOP…

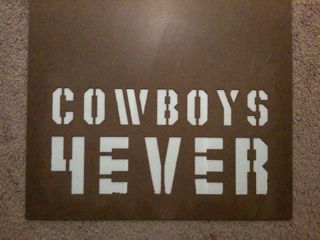

BOTTOM…

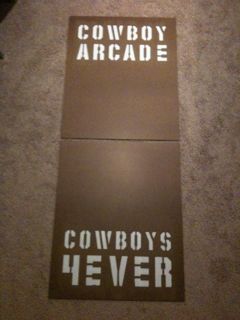

and the WHOLE THING:

I still need to clean up the edges some, drill the mounting holes, and the paint them black.

So what do you think given that this is something no one will even see

🙂

Leave a Reply

You must be logged in to post a comment.